|

VRD Tester is a test unit designed to

test all current DC VRD units on the market today.

The series 3 is necessary because it

is not possible to load many welders to a high enough

current using resistors in a hand held tester

Some welding machine models in the

Cigweld,Lincoln,Kemppi & SafeTac range require a

load of 30 or more amps to turn the VRD off & on

Unit has an internal 200 Ohm resistor

& a programmable microprocessor precision voltage

indicator to indicate the transition from less than 35

VDC (Green LED) to above 36 Volts DC (Flashing Red LED)

The unit works by connecting leads

pressing button to turn the unit on then welding at 90 to

150 Amps for 2 to 3 seconds.

It is still possible to test some

Welding machines without welding with the optional

load resistor.

Unit will automatically power down after 3

minutes to increase battery

Tester can be programmed to suit

different voltages if required

Series 3 Tester will also work with wired handpiece tig triggers & remote RF type electrode holder trigger switch devices

Tester comes with adaptors to suit all

types of welding terminal such as Stud, Lincoln

mech-connectors, Small dinse on inverters & large

Dinse on 200 amp plus machines.

Inline tester makes connection to

welding machine easier & safer than other methods

currently used.

|

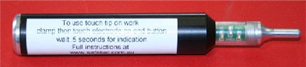

VRD Tester is a test unit designed to

operate with all SafeTac VRD units. It is a cylindrical

rod with a green or red button one end and a brass

lug on the other.

With a brass button in the middle, testing is accomplished

by touching the brass end onto the work clamp then

placing the electrode onto the central brass button

and pressing the test button.

The test procedure is etched onto the

304 s/s plate, which is attached to the H/D canvas

carry bag.

Upper test resistance has been increased

from 180 Ohms to 200 Ohms +/- 1% (1674.2 2003)VRD

turn on point and 40 ohms VRD turn off point. The

series 2 tester now works with Cigweld and Eutectic

VRD products plus many other Factory VRD units set

close to the 200 Ohm maximum resistance VRD turn on

point.

The series 2 unit can be identified

by the no 2 stamped on the end of the brass test lug.

At no time is the operator in contact with the welder

output whilst testing.

Unit Length 290mm Diameter 38mm Weight

including carry bag 705 grams

|

|

|

Programmable Microprocessor controlled

(Patent Pending) allows simple pass/fail testing of

welding machines output voltage for compliance to

AS 1674.2 2003,also quick check for safe electrode

holder voltage before handling electrode (test time

less than 1.5 seconds).

- 3 to 180 VAC/VDC input auto polarity AC/DC auto

detect, auto turn on /off fuse protected

- Indication Steady Green less than 35 VDC &

25 VAC RMS Flashing Red Voltage is greater than

35.5 VDC & 26 VAC RMS,Steady Blue indicates

voltage being tested is AC Red & Green Flashing

simultaneously indicates battery needs changing

- Light weight pocket tester with built in sleep

mode (1 year battery life normal operation) auto

detects and turns on when welder voltage is being

applied probe turns off when test is complete.

- Standard factory setting indicates test min/max

voltage levels set in Australian Standards 1674.2

2003

- AC & DC Pass & Fail indication levels

can be adjusted between DC 3 to 180 VDC AC 3.5 to

180 VAC Peak to suit site requirements.

Note : Test on non - VRD Welder

(67 VAC) OCV

Red on indicating over -voltage Blue on indicating

AC

|

|

|

|

|

The N.A.T.A. calibrated test unit is

fitted with 0-50-100-150-200 Ohm tapings for testing

calibration on most VRD units for correct operation

and compliancy with Australian Standards 3195 &

1674.2 2003 ,unit is supplied with original Western

Power N.A.T.A. lab no 47 test certificate. Terminals

are clearly marked and each unit is serial numbered.

Test procedure and instructions are included .

|

|